In today’s fast-paced world, advanced robotics stands at the forefront of technological innovation. These cutting-edge machines are revolutionizing industries, transforming how tasks are performed, and enhancing human capabilities. From manufacturing to healthcare, robotics is reshaping the landscape of productivity and efficiency.

With developments in artificial intelligence, machine learning, and sensor technology, robots are becoming increasingly sophisticated. They’re not just tools but intelligent systems capable of adapting to complex environments and making real-time decisions. This article delves into the fascinating realm of advanced robotics, exploring its applications, challenges, and the future it promises.

Table of Contents

ToggleOverview of Advanced Robotics

Advanced robotics encompasses the design, construction, operation, and use of robots equipped with complex algorithms and sensors. These robots integrate artificial intelligence, enabling them to learn and adapt, thus enhancing their functionality. Key applications include manufacturing, healthcare, logistics, and agricultural sectors.

Key Components

- Artificial Intelligence: AI enables robots to learn from data, improving their decision-making capabilities and efficiency in task execution.

- Sensor Technology: Advanced sensors allow robots to perceive their environment accurately, facilitating navigation and interaction with objects and humans.

- Actuation and Control: This involves the methods by which robots physically interact with their surroundings, using motors and actuators for precise movements.

Applications of Advanced Robotics

- Manufacturing: Automated assembly lines utilize robots for precision tasks, increasing production rates and reducing error margins.

- Healthcare: Surgical robots enhance procedural accuracy, while robotic exoskeletons assist patients in rehabilitation.

- Logistics: Autonomous vehicles and drones optimize supply chain operations, improving delivery times and reducing labor costs.

- Agriculture: Robots assist in planting, harvesting, and monitoring crops, resulting in increased yield and resource efficiency.

Challenges Facing Advanced Robotics

- Integration with Existing Systems: Ensuring new robots work seamlessly with current infrastructures poses significant hurdles.

- Cost of Development: High initial investment costs can limit accessibility for smaller businesses.

- Ethical Considerations: The deployment of robots raises ethical questions regarding job displacement and decision-making in critical situations.

- Safety Regulations: Establishing comprehensive safety standards remains challenging, requiring ongoing dialogue among stakeholders.

Advanced robotics continues to evolve, driving innovations that reshape how industries operate. The development of autonomous systems demonstrates the potential for improved efficiency, productivity, and safety across various domains.

Key Technologies in Advanced Robotics

Advanced robotics relies on several key technologies that enhance the capabilities of robotic systems, making them more efficient and adaptable across various applications.

Artificial Intelligence Integration

Artificial intelligence (AI) integration significantly uplifts the functionality of robots. AI enables robots to analyze large datasets, recognize patterns, and make autonomous decisions. For example, in manufacturing, AI-powered robots adjust production schedules based on real-time demand data, optimizing efficiency. In healthcare, AI enhances surgical robots’ precision, allowing for minimally invasive procedures that improve patient outcomes. Continued developments in AI algorithms and neural networks enhance robots’ learning capabilities, further transforming industries.

Machine Learning Applications

Machine learning (ML) is a subset of AI focusing on algorithms that enable robots to learn from data. ML applications in robotics include predictive maintenance, where robots analyze performance data to foresee malfunctions. In logistics, ML helps autonomous vehicles navigate complex environments by learning from past experiences. Robots equipped with ML can adapt to new tasks and environments, increasing their usability and effectiveness. The growth of ML technologies leads to robots that continuously improve their capabilities based on updated information.

Sensors and Actuators

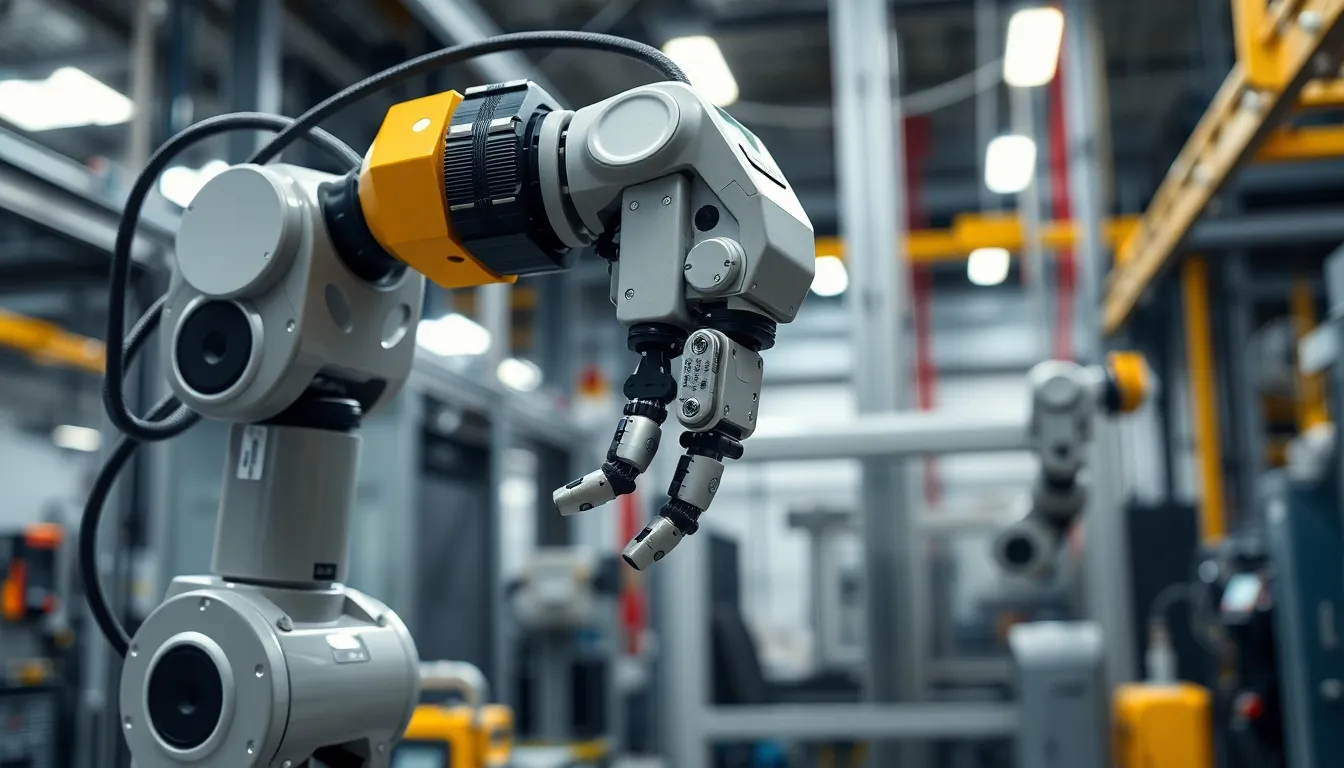

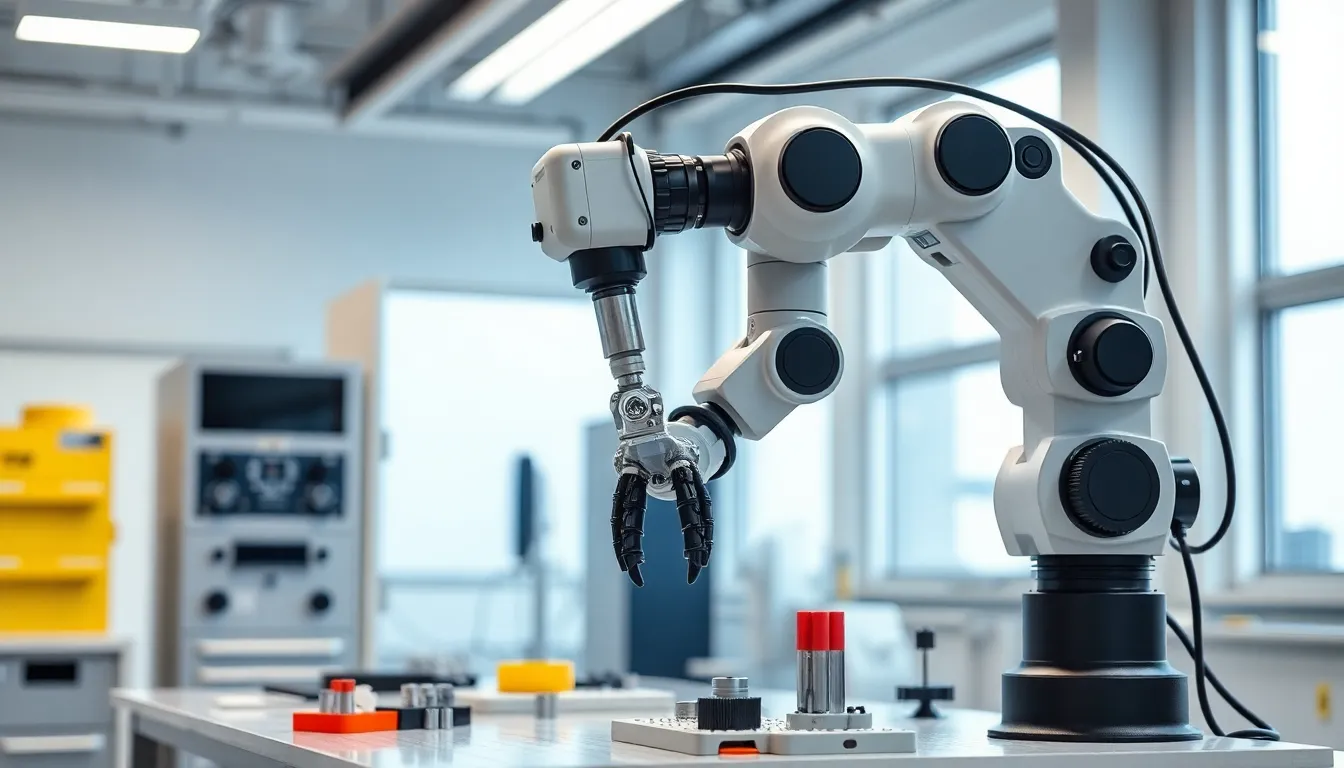

Sensors and actuators are integral components in advanced robotics, allowing for precise environmental interaction. Sensors collect data from surroundings, including visual, auditory, and tactile information, enhancing robots’ situational awareness. For instance, proximity sensors enable robots to navigate safely around obstacles. Actuators provide the movement and manipulation necessary for robots to perform tasks; they convert energy into motion, whether for simple movements or complex operations. Together, advanced sensor and actuator technologies empower robots to operate effectively in dynamic environments, fulfilling their designated roles efficiently.

Applications of Advanced Robotics

Advanced robotics showcases remarkable applications across numerous sectors, driving efficiency and innovation. Industries leverage these sophisticated machines to transform traditional operations, enhancing capabilities and outcomes.

Industrial Automation

Advanced robotics plays a crucial role in industrial automation, streamlining processes in manufacturing settings. Robots perform repetitive tasks such as welding, painting, and assembly with speed and precision, resulting in reduced operational costs. Companies implement automated guided vehicles (AGVs) for material transport, improving overall warehouse efficiency. Collaborative robots, or cobots, work alongside human operators, increasing productivity through seamless interaction and adaptability. Notable industries include automotive, electronics, and consumer goods, where robotics integrates with existing systems to enhance production rates while maintaining safety standards.

Healthcare Innovations

Advanced robotics revolutionizes healthcare through innovations in surgery, rehabilitation, and patient care. Surgical robots, like the da Vinci Surgical System, enable minimally invasive procedures with superior accuracy, reducing recovery times for patients. Robotic exoskeletons assist individuals with mobility impairments, promoting independence and enhancing physical therapy. Telepresence robots facilitate remote consultations, allowing healthcare professionals to monitor patients effectively. Robotics also aids in drug delivery and lab automation, delivering medications and conducting tests efficiently. These advancements significantly improve patient outcomes and streamline healthcare operations.

Exploration and Research

Robots play an essential role in exploration and research, particularly in environments challenging for humans. Drones and underwater robots assist in geological surveys, environmental monitoring, and disaster response. They provide real-time data collection and analysis, enhancing scientific research capabilities. Space exploration benefits from advanced robotics through rovers like NASA’s Perseverance, designed to traverse Martian terrain and conduct experiments. These robotic systems gather valuable information, contributing to scientific discoveries and expanding human understanding of various environments.

Challenges and Ethical Considerations

Advanced robotics pose challenges that require thoughtful consideration of safety and ethical implications. As these technologies advance, addressing critical issues becomes essential.

Safety Concerns

Safety represents a primary concern in advanced robotics. Robots operate in environments where human workers are present. Risks include mechanical failures, software errors, and unintended interactions with people. Compliance with safety standards is crucial for preventing accidents. Robots must undergo rigorous testing and certification processes, ensuring reliability in real-world applications. Manufacturers implement safety measures such as emergency stop functions and sensory feedback systems, reducing potential hazards.

Adopting collaborative robots, or cobots, enhances safety by allowing humans and robots to work side by side. Cobots are designed with advanced sensors that detect nearby human presence, enabling a safer working environment. Continuous monitoring of robot performance aids in identifying issues before they escalate, thus safeguarding human workers.

Job Displacement

Job displacement arises as an ethical consideration in advanced robotics deployment. Automation of tasks traditionally performed by humans can lead to workforce reductions. Industries that heavily rely on manual labor are particularly vulnerable. Studies indicate that millions of jobs could be affected in sectors like manufacturing and retail.

While automation improves efficiency, it necessitates reskilling and upskilling of the workforce. Stakeholders must consider strategies for job transition, emphasizing the importance of developing training programs. These initiatives facilitate smooth transitions for affected workers into new roles within technology-driven sectors.

Balancing technological advancement with socio-economic impacts is critical. Ethical frameworks must guide the integration of robots into various industries, ensuring that technology complements human labor rather than replaces it.

Future Trends in Advanced Robotics

Automation integration becomes a significant trend in advanced robotics. Companies adopt robots designed to work alongside workers, enhancing productivity without large-scale job losses. This approach fosters environments where human workers and robots collaborate efficiently.

Data-driven decision-making continues to evolve. Robots equipped with advanced artificial intelligence will analyze enormous data sets in real-time, improving operational efficiency across sectors. For instance, logistics companies may rely on AI-enhanced robots to optimize delivery routes dynamically.

Human-robot interaction improves through intuitive user interfaces. Future robots will feature advanced communication abilities, enabling seamless communication with human operators. Enhanced sensory systems will allow robots to interpret human emotions and adapt accordingly.

Ethical AI development gains importance. Industry leaders recognize the necessity of establishing guidelines to ensure robots act responsibly and in accordance with human values. This trend promotes transparency in AI algorithms and fosters trust among users and stakeholders.

Market diversification leads to increasing applications in various sectors. Advanced robotics technologies will penetrate new fields like retail, disaster response, and elder care. Increased demand for customizable solutions will drive innovation, allowing robots to address specific needs and improve user experience.

Research and development will focus on sustainability. Future robotic systems will prioritize energy efficiency and reduced environmental impact. Organizations will invest in developing energy-efficient algorithms and eco-friendly materials for robot construction.

Collaboration between robotics, IoT, and big data will transform industries. Smart robots equipped with Internet of Things (IoT) capabilities will share data with other devices, enhancing overall system performance. The integration of big data analytics will enable predictive maintenance, reducing downtime and costs.

Lastly, advancements in soft robotics will reshape design concepts. Future robots will employ flexible materials that mirror human-like movements, enabling delicate interactions in sensitive environments, such as healthcare and home assistance. Soft robotics will expand capabilities in agricultural applications, enabling precise handling of crops without damage.